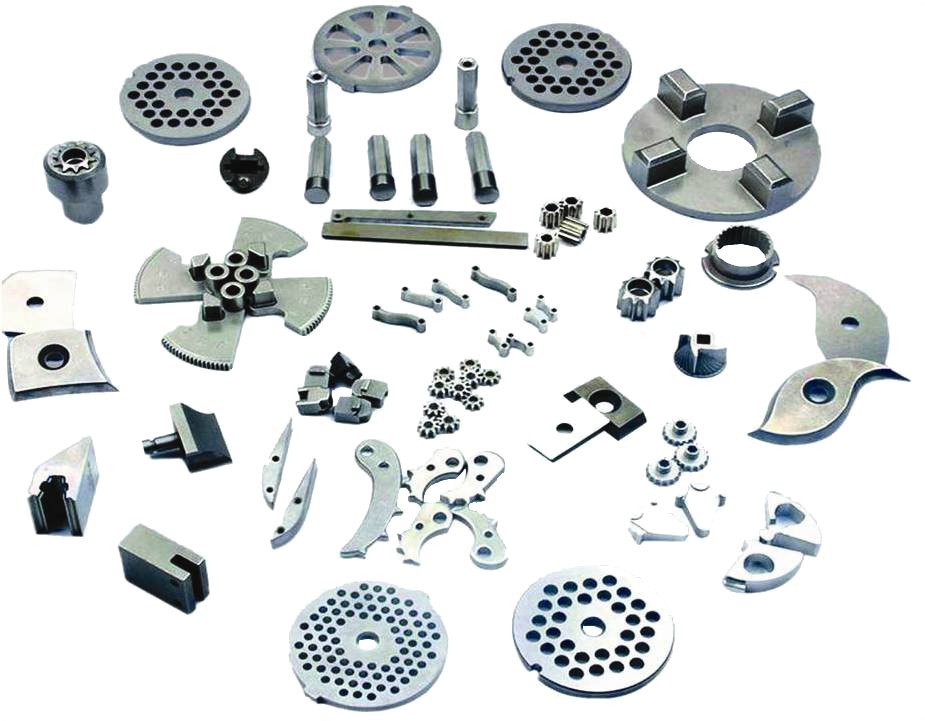

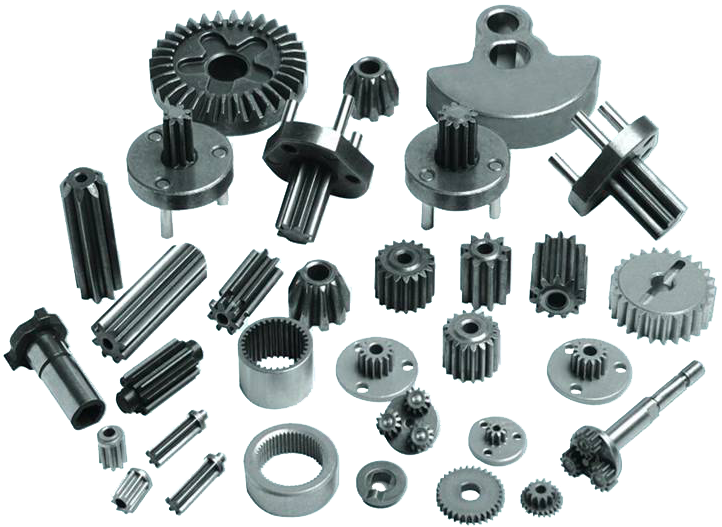

PM Metal Powder Metallurgy Pressing Process for Power Tools, Automotive

Products such as gears produced by our metal powder pressing molding process can reach a density of 6.5 to 7.1g/cm³.

Based on the size of the powder pressed product, the finished product accuracy that our pressing process can achieve is as shown in the table below.

| Product Size (mm) | Accuracy (mm) |

| 0-3 | ±0.05 |

| 3-6 | ±0.1 |

| 6-15 | ±0.15 |

| 15-30 | ±0.2 |

| 30-50 | ±0.3 |

| 50-100 | ±0.6 |

| 100-200 | ±0.7 |

Parts produced by the metal powder pressing process have unique chemical compositions and mechanical and physical properties that cannot be obtained using traditional melting and casting methods.

Metal powder pressing technology can be used to directly make porous, semi-dense or fully dense materials and products, such as oil-impregnated bearings, gears, cams, guide rods, cutting tools, etc. It is a low-cutting process.

The pressed metal powder process has the following advantages

- No or minimal cutting required

- Material utilization rate up to 97%

- Manufacturing tolerances on part dimensions are tight and reproducible

- Material composition adjustable

- Parts have good surface finish

- Can be heat treated to increase strength and wear resistance

- For self-lubricating or filtration purposes, materials or articles with controlled porosity are available

- Can produce parts with complex or strange shapes that cannot be produced by other metal forming processes

- Suitable for medium to high volume part production

Metal powder pressing is a process for manufacturing metal parts and products. The process generally includes multiple stages such as powder preparation, powder mixing and pressing, sintering or hot pressing. The following is a typical process of powder metallurgy:

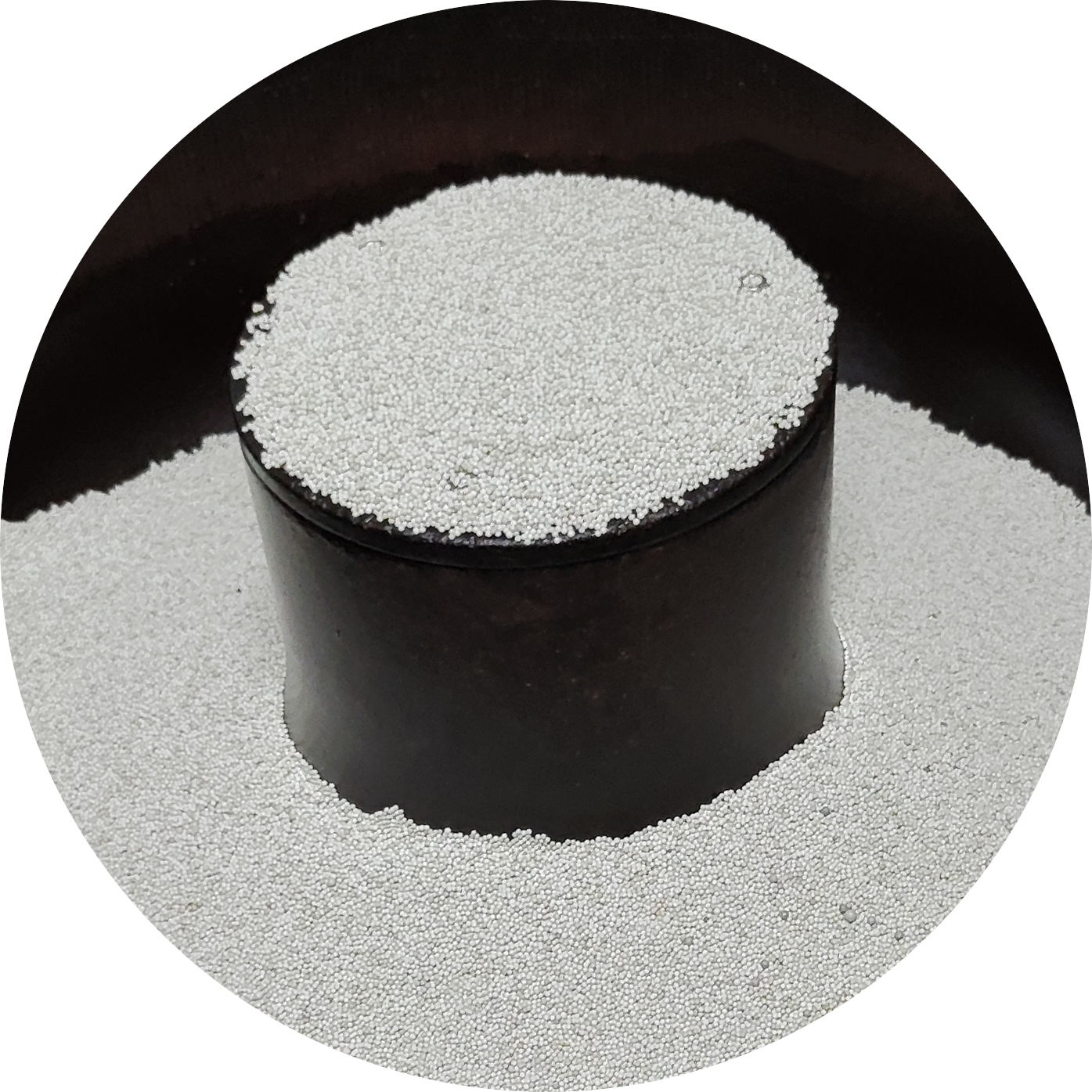

1. Metal Powder Preparation and Powder Mixing

First, the raw metal or alloy is processed into small particle powder. The process can be carried out by different methods, such as mechanical grinding, atomization, chemical methods, etc.

The purity of the powders we manufacture can reach 99.9%, and we can also develop special powders according to your product needs.

Workers put the prepared powder into the mixer and mix it to produce metal powder suitable for your product requirements for powder pressing and molding.

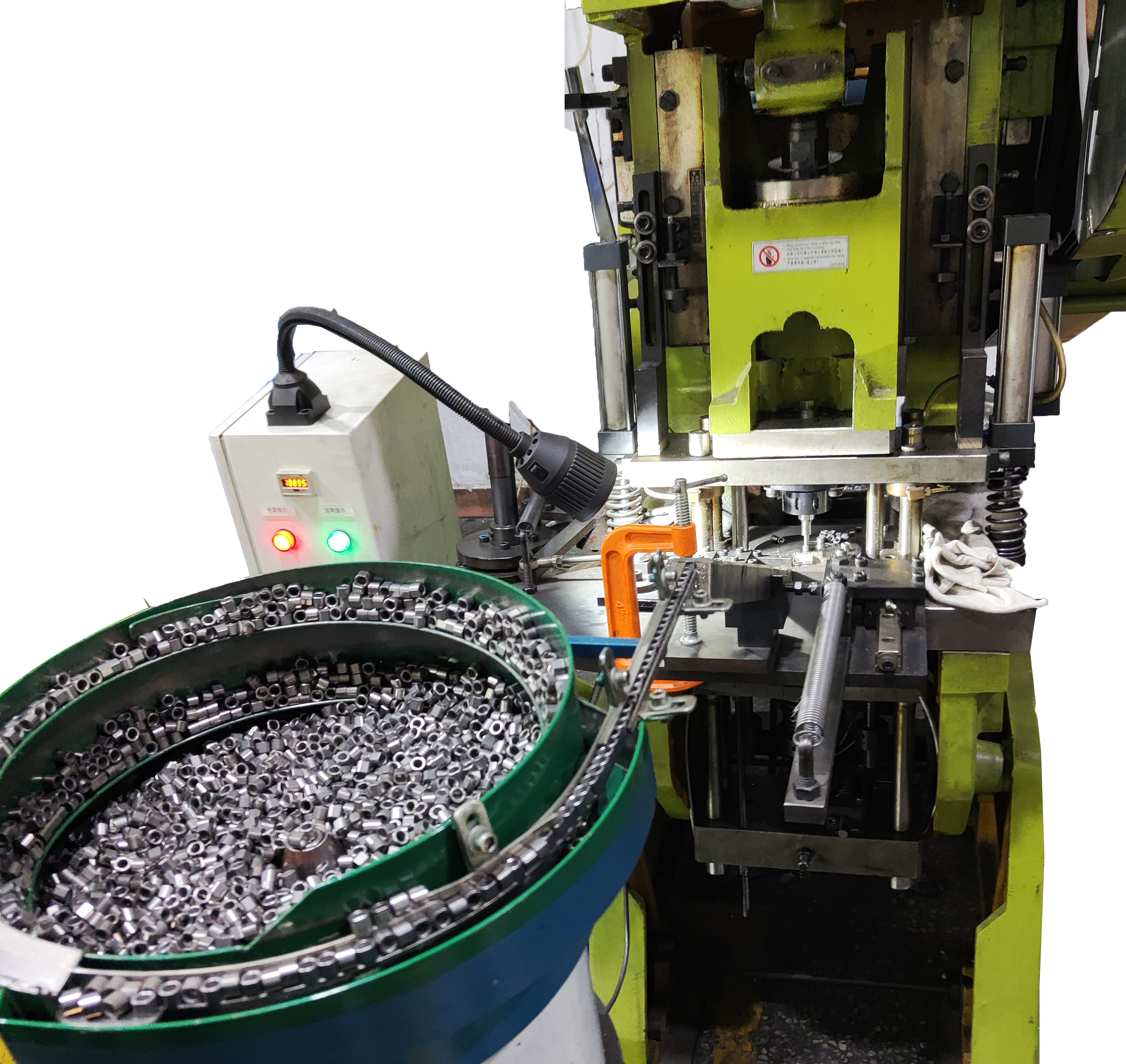

2. Metal Powder Press Molding (PM)

Different metal powders are mixed together in the required proportions, and the right amount of additives are added to improve the properties of the material. The mixed powder is then pressed into a blank of the desired shape through a pressing process.

We have many types of metal press forming machines,

6-ton press forming machine *12 units

15 tons press forming machine *2 sets

25-ton press forming machine *6 units

60-ton press forming machine *12 units

100-ton press forming machine *2 units

30-ton hydraulic press *3 sets

300-ton hydraulic press *1 set

They can meet the needs of high-volume and efficient PM process production.

3. Sintering or Hot Pressing

The pressed green embryo is placed in a sintering furnace or vacuum sintering furnace with a protective atmosphere for sintering or hot pressing. During the sintering process, powder particles undergo a series of physical and chemical processes such as diffusion, recrystallization, welding, combination, and dissolution to become metallurgical products with a certain porosity. Sintering can be solid phase sintering, liquid phase sintering or gas phase sintering.

We have ammonia sintering furnaces suitable for sintering carbon steel parts and stainless steel parts. The vaporized liquid ammonia flows through an ammonia decomposition furnace equipped with a catalyst and is decomposed into hydrogen and nitrogen according to the reaction of 2NH3→N2+3H2. Drying and adsorption sintering improve the strength of the green body.

4. Post-Processing Process

Generally, the sintered parts can be used directly. However, for some parts that require high dimensional accuracy and high hardness and wear resistance, post-sintering treatment is required, including precision pressing, rolling, extrusion, quenching, surface quenching, oil immersion, and infiltration, etc.

The finished product after sintering or hot pressing sometimes requires further processing, such as surface coating, heat treatment, heat treatment, processing, etc.

We have a variety of post-processing equipment dedicated to the PM process, such as

Lathe *1 set

Drilling Machine *2 sets

Vibration Grinder *2 sets

Magnetic Polishing *1 set

Vacuum Immersion Oil *2 sets

Dryer *2 sets

After processing by these equipment, the accuracy, hardness and wear resistance of metal powder metallurgy parts can be improved.

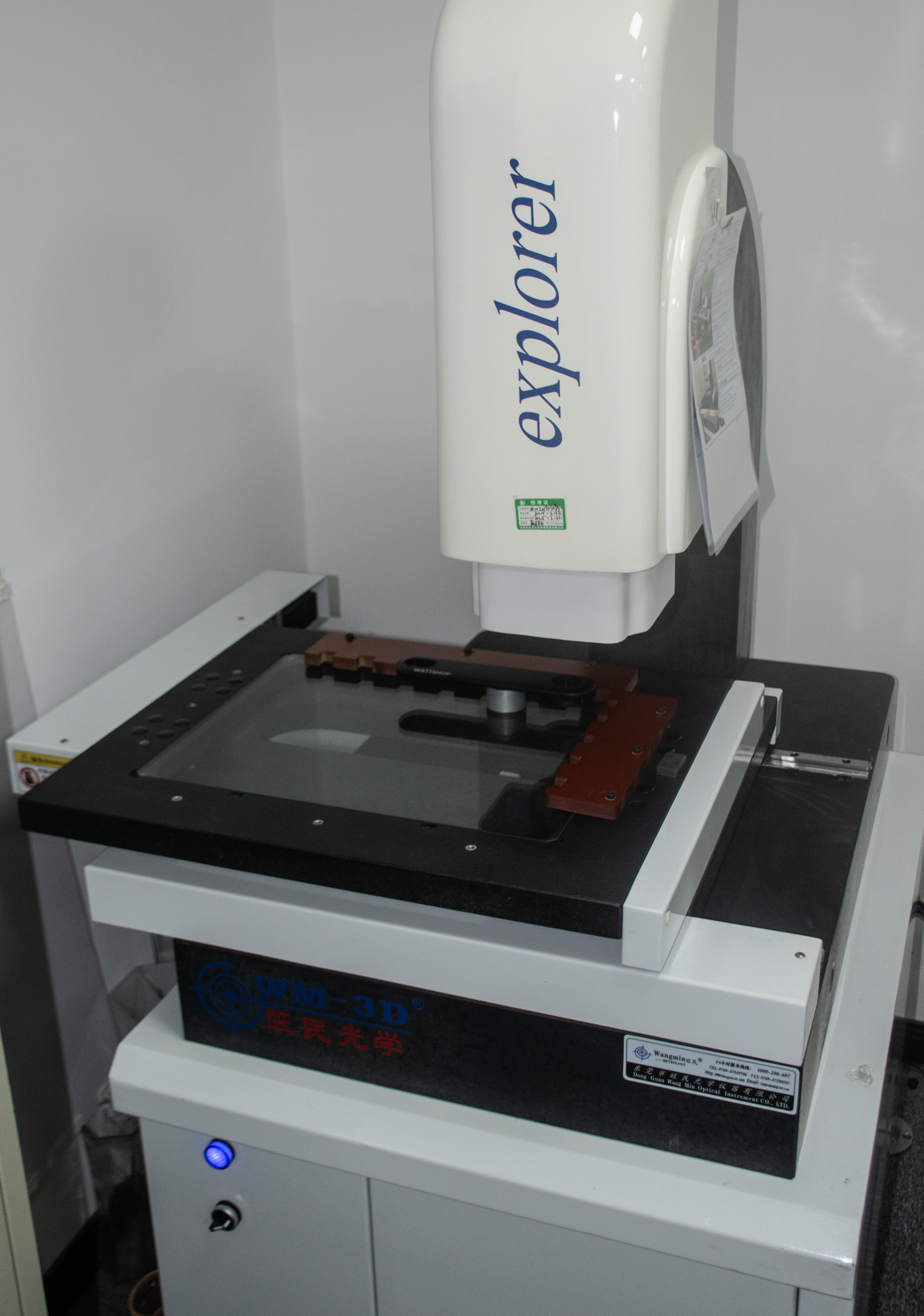

5. Inspection and Inspection

Finally, the finished parts or items need to be inspected and inspected. Our testing equipment, electronic specific gravity leveling, hardness tester, tensile tester, etc. are suitable for PM process. They can ensure that PM products meet the design requirements and quality standards.

The metal powder pressing metallurgical process has the advantages of high efficiency, low cost, short production cycle, and precise control of the forming process. It is widely used in the manufacturing fields of automobiles, electronics, machinery and other industries.

Feel free to click the to learn more.